Whatsapp:+86-18638891360sales@fv-bearing.com

FV four-row taper roller bearings are installed as complete assemblies and take axial loads in addition to heavy radial loads, so that generally it is not requested separate thrust bearings in such arrangements.

They are commonly used in rolling mill applications.

For quick roll changes, the bearings have a loose fit on the roll necks, but there is the disadvantage that the inner rings wander on their seatings causing wear. To reduce these negative effects, FV bearings have a helical groove in the bore and lubrication grooves in the side faces of the inner rings. These grooves enable lubricant to be supplied to the contact surfaces of the inner ring and seating.

Since wear and shock resistance under heavy rolling loads is a requirement for roll neck bearings, highest quality carburizing grade bearing alloy steels are normally used in FV four-row taper roller bearings.

Besides, for large size bearings, pierced rollers and steel pin-type cage for maximum load ratings possible are applied.

The induced thrust resulting from radial loading is cancelled within the double cones and it eliminates excessive loads on clamping and spacing members.

FV produces this style of bearings in two base designs, TQO and TQI configuration, where the main difference is the mutual arrangement of the roller complements and the number of inner and outer rings dictated by this.

The TQO type is composed in its standard configuration of two double cone assemblies, one central double cup, two single cups and factory adjusted cup and cone spacers.

The spacers of each bearing are face ground after accurate measurement of the distance between adjacent cups and cones to obtain the asked initial play (also defined as BEP - Bench End Play). So the bearing parts cannot be interchanged and they are individually marked for proper assembly.

Lubrication grooves and oil holes are provided in the cup spacers and in the double cup. Furthermore, lubricant slots in the cones side faces and cone spacer permit the lubricant to go through the bearing to the roll neck.

These bearings can be provided with lateral extension of the double cones used as sealing surface. This sealing feature offers better protection against hostile environment.

For high speed rolling mill requirements, the TQO bearing sets may have tapered bore with features of high capacity, compactness and a mounting system that guarantees a positive interference fit on the roll neck.

The TQI type is composed in its standard configuration of one double cone assembly, two single cone assemblies and two double cups.

A four-separated individual single cup configuration is also available. This design facilitates the reworking of the bearing.

These bearings are fitted with pressed steel cage or with pierced rollers and steel pin-type cage. The fact that contact angles diverge makes the bearings well suited to resist to warping and misalignment.

The version with tapered bore that, with its three-cone design, assures easy assembly and disassembly (designation TQIT and TQITE) is also available.

In FV sealed TQOS type sets, four-row taper roller bearings have been developed to improve the lubrication in service. The incorporation of this type of bearing simplifies design, reduces grease consumption and routine maintenance requirements and attains longer service life.

The seals, fitted on both sides of the bearing set, are produced in several designs depending on bearing size and application needs; the most common ones are the integrated lateral unitized seals (European version), the integrated lateral narrow seals (compact seal concept) and the loose flange lateral unitized seals (Japanese version).

So the basic design with the garter seal, made by reinforced fluoro rubber and steel spring, is located in the integral external cups.

Alternatively, the separate seal carrier flanges are matched to the cups and a chock type seal runs on extended surface of inner rings.

Furthermore, FV seals have been redesigned in new type to increase seal durability and efficiency: while maintaining an overall narrow profile, these seals optimize the available space by utilizing the area directly adjacent to or underneath the cage bore, with the result of the usage of longer rollers with consequent increased bearing capacity similar to open type version.

FV sealed four-row taper roller bearings are usually provided also with O-rings in the outboard cup outside diameter to seal contaminants from the bearing outer diameter and/or with a cone seal set designed to accommodate relative motion between inner rings and to prevent build-up of negative pressure (anti-vortex system technology for longer bearing life and less lubricant deterioration).

Phosphate treatment for rings, rollers and spacers (suffix PT4) for anti-rust and anti-corrosion properties under water, alkalescent and acidescent working conditions is also available.

FV produces special executions of TQO made of four single cups and two double cone assemblies (design without spacers).

Most of TQO and TQI four row taper roller bearings are manufactured with inch dimensions as per American AFBMA 19/1974 and as per FV standard practice, dimensional and running accuracy grade is in accordance with class 2 or 4.

For more technical parameters of the bearings, please check the following list:

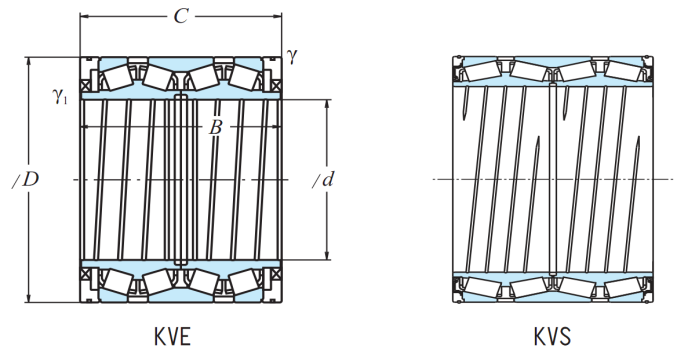

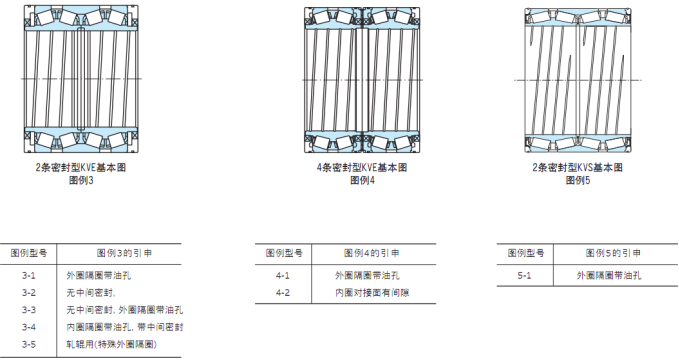

|

Designation (STF) |

Design (fig.) |

Dimensions (mm) |

Basic load ratings (KN) |

Wt (Kg) | ||||||

| d | D | B | C |

ri (min) |

r (min) |

Cr | Cor | approx. | ||

| 101KVE2051 | 3-2 | 101.6 | 200.025 | 320 | 320 | 1 | 3 | 1450 | 2420 | 47.8 |

| 150KVE2101E | 3-1 | 150 | 210 | 240 | 240 | 1 | 2.5 | 990 | 2270 | 26.1 |

| 170KVS2401Eg | 5 | 170 | 240 | 175 | 175 | 2.5 | 2.5 | 1010 | 2000 | 23 |

| 187KVE2651E | 3-1 | 187.325 | 269.875 | 230 | 230 | 2 | 3.3 | 1460 | 3200 | 43.6 |

| 215KVS2851Eg | 5 | 215.9 | 288.925 | 177.8 | 177.8 | 0.8 | 3.3 | 1070 | 2350 | 38 |

| 216KVS3351Eg | 5 | 216.103 | 330.2 | 263.525 | 269.875 | 1.5 | 3.3 | 2290 | 4550 | 77 |

| 220KVE2902 | 4-1 | 220 | 295 | 315 | 315 | 1 | 2.5 | 1410 | 3450 | 61.2 |

| 220KVE2901 | 4-1 | 220 | 295 | 335 | 335 | 1 | 2.5 | 1410 | 3450 | 65 |

| 220KVE3001E | 3-2 | 220 | 300 | 270 | 270 | 2.5 | 2.5 | 1650 | 4000 | 56.5 |

| 220KVE3201E | 3 | 220 | 320 | 290 | 290 | 1.5 | 2.5 | 1970 | 4500 | 78.7 |

| 220KVS3301Eg | 5 | 220 | 330 | 260 | 260 | 4 | 3 | 2330 | 4800 | 76 |

| 225KVE3201E | 3 | 225 | 320 | 230 | 230 | 1 | 2 | 1510 | 3300 | 59.9 |

| 228KVE4052E | 3 | 228.6 | 400.05 | 296.875 | 296.875 | 3.3 | 3.3 | 2410 | 4250 | 161 |

| 234KVS3251Eg | 5 | 234.95 | 327.025 | 196.85 | 196.85 | 1.5 | 3.3 | 1550 | 3200 | 49 |

| 240KVE3202E | 3 | 240 | 320 | 250 | 250 | 3 | 3 | 1510 | 3700 | 56.3 |

| 240KVE3301E | 3 | 240 | 338 | 248 | 248 | 2 | 3 | 1820 | 4000 | 70.6 |

| 240KVE3302E | 3 | 240 | 338 | 290 | 290 | 2 | 3 | 2120 | 5000 | 82.6 |

| 244KVS3251Eg | 5 | 244.475 | 327.025 | 193.68 | 193.68 | 1.5 | 3 | 1450 | 3300 | 43 |

| 245KVS3402Eg | 5 | 245 | 345 | 310 | 310 | 2 | 3 | 2700 | 6650 | 85 |

| 250KVE3601AE | 3 | 250 | 365 | 270 | 270 | 2.5 | 3 | 2210 | 4650 | 96 |

| 250KVE3601E | 3-1 | 250 | 365 | 270 | 270 | 2.5 | 3 | 2210 | 4650 | 96 |

| 254KVS3552Eg | 5 | 254 | 358.775 | 269.875 | 269.875 | 1.5 | 3.3 | 2420 | 5500 | 86 |

| 260KVS3601Eg | 5 | 260 | 365 | 340 | 340 | 2.7 | 4 | 2960 | 7350 | 110 |

| 260KVS3651Eg | 5 | 260 | 365 | 340 | 340 | 2.5 | 4 | 2960 | 7350 | 110 |

| 260KVS4251Eg | 5 | 260.35 | 422.275 | 314.325 | 317.5 | 6.4 | 3.3 | 3600 | 7050 | 170 |

| 266KVS3551Eg | 5 | 266.7 | 355.6 | 230.188 | 228.6 | 1.5 | 3.3 | 1960 | 4600 | 62 |

| 276KVS3952Eg | 5 | 276.225 | 393.7 | 269.875 | 269.875 | 1.5 | 3.3 | 2720 | 6100 | 105 |

| 279KVS3952Eg | 5 | 279.4 | 393.7 | 269.875 | 269.875 | 1.5 | 6.4 | 2720 | 6100 | 102 |

| 279KVE3951E | 3 | 279.4 | 393.7 | 270.63 | 269.875 | 1.5 | 6.4 | 2290 | 5150 | 105 |

| 279KVS3954Eg | 5 | 279.4 | 393.7 | 320 | 320 | 1.5 | 6.4 | 3100 | 7350 | 120 |

| 279KVE4101 | 4 | 279.4 | 410 | 420 | 420 | 1 | 6.4 | 3300 | 7400 | 190 |

| 280KVE3801E | 3 | 280 | 380 | 290 | 290 | 1.5 | 3 | 2230 | 5350 | 96.2 |

| 280KVE3901E | 3-4 | 280 | 395 | 340 | 340 | 1.5 | 2.5 | 2950 | 7050 | 133 |

| 280KVE3902E | 3 | 280 | 395 | 340 | 340 | 1.5 | 2.5 | 2950 | 7050 | 133 |

| 280KVE4101E | 3-4 | 280 | 410 | 268 | 268 | 1.5 | 6.4 | 2330 | 4600 | 121 |

| 280KVE4102E | 3-1 | 280 | 412 | 340 | 340 | 3 | 3 | 3300 | 7400 | 156 |

| 290KVS4001Eg | 5 | 290 | 400 | 346 | 346 | 3 | 4 | 3250 | 8400 | 112 |

| 304KVS4351Eg | 5 | 304.648 | 438.048 | 280.99 | 279.4 | 3.3 | 3.3 | 3100 | 6750 | 132 |

| 304KVE4351E | 3-2 | 304.648 | 438.048 | 281.74 | 279.4 | 3.3 | 3.3 | 2630 | 5600 | 140 |

| 304KVS4151Eg | 5 | 304.8 | 419.1 | 269.875 | 269.875 | 1.5 | 6.4 | 2850 | 6550 | 111 |

| 304KVS4152Eg | 5 | 304.902 | 412.648 | 266.7 | 266.7 | 1.5 | 3.3 | 2760 | 6500 | 100 |

| 310KVS4301Eg | 5 | 310 | 430 | 310 | 310 | 3 | 3 | 3350 | 8200 | 140 |

| 310KVS4302Eg | 5 | 310 | 430 | 350 | 350 | 2.7 | 3 | 3700 | 9550 | 155 |

| 317KVS4251Eg | 5 | 317.5 | 422.275 | 269.875 | 269.875 | 1.5 | 3.3 | 2740 | 6750 | 100 |

| 317KVE4451E | 3 | 317.5 | 447.675 | 367 | 367 | 2.5 | 3 | 3450 | 8100 | 184 |

| 343KVS4551Eg | 5 | 343.052 | 457.098 | 254 | 254 | 1.5 | 3.3 | 2830 | 6700 | 110 |

| 343KVE4561E | 3 | 343.052 | 457.098 | 299 | 299 | 1.5 | 3.3 | 2830 | 6950 | 137 |

| 355KVS4551Eg | 5 | 355.6 | 457.2 | 252.412 | 252.412 | 1.5 | 3.3 | 2650 | 6750 | 98 |

| 395KVE5401E | 3-1 | 395 | 545 | 360 | 360 | 2.5 | 5 | 3600 | 9050 | 255 |

| 406KVS5451Eg | 5 | 406.4 | 546.1 | 288.925 | 288.925 | 1.5 | 6.4 | 3950 | 9450 | 184 |

| 406KVE5454E | 4-1 | 406.4 | 546.1 | 346 | 346 | 0.5 | 6.4 | 2560 | 5800 | 231 |

| 420KVE5901E | 3-1 | 420 | 590 | 395 | 375 | 2.5 | 5 | 3550 | 8200 | 332 |

| 440KVE5901E | 4-1 | 440 | 590 | 510 | 510 | 4 | 4 | 5450 | 14300 | 396 |

| 440KVE6201E | 3-1 | 440 | 620 | 454 | 454 | 4 | 6 | 6500 | 15700 | 435 |

| 450KVS5901Eg | 5 | 450 | 595 | 368 | 368 | 4 | 5 | 5550 | 15000 | 272 |

| 457KVS5951Eg | 5 | 457.2 | 596.9 | 276.22 | 279.4 | 1.5 | 3.3 | 4000 | 9850 | 206 |

| 460KVE5901E | 3-1 | 460 | 590 | 470 | 470 | 2.5 | 5 | 4900 | 14100 | 322 |

| 480KVE6101A | 4-2 | 480 | 615 | 435 | 435 | 3 | 5 | 4650 | 12800 | 323 |

| 480KVE6702E | 4-1 | 480 | 678 | 574 | 574 | 3 | 5 | 8400 | 21500 | 662 |

| 482KVS6151Eg | 5 | 482.6 | 615.95 | 330.2 | 330.2 | 4.3 | 6.4 | 4900 | 13500 | 235 |

| 482KVE6152E | 3 | 482.6 | 615.95 | 330.2 | 330.2 | 4.3 | 6.4 | 3650 | 9650 | 243 |

| 482KVE6155E | 3 | 482.6 | 615.95 | 419.1 | 402.05 | 2.3 | 6.4 | 4700 | 13600 | 302 |

| 482KVE6453E | 3-5 | 482.6 | 647.7 | 417.512 | 417.512 | 3.3 | 6.4 | 5500 | 13800 | 392 |

| 488KVE6251E | 4 | 488.95 | 622.3 | 365.125 | 365.125 | 3.8 | 6.4 | 3450 | 8950 | 272 |

| 490KVE6201A | 4-2 | 490 | 625 | 435 | 435 | 3 | 5 | 4550 | 12500 | 329 |

| 509KVE6554E | 3 | 509.948 | 654.924 | 377 | 379 | 1.5 | 6.4 | 4800 | 13000 | 321 |

| 520KVE7301E | 3-1 | 520 | 735 | 535 | 535 | 5 | 6 | 8800 | 22700 | 726 |

| 558KVE7351E | 3-3 | 558.8 | 736.6 | 540 | 540 | 3.3 | 6.4 | 8950 | 25300 | 625 |

| 595KVE8451E | 3 | 595.312 | 844.55 | 615.95 | 615.95 | 1.5 | 6.4 | 12600 | 33000 | 1110 |

| 595KVE8452E | 4 | 595.312 | 844.55 | 615.95 | 615.95 | 3.3 | 6.4 | 10900 | 27200 | 1110 |

| 609KVE7851E | 3 | 609.6 | 787.4 | 361.95 | 361.95 | 1.5 | 6.4 | 5450 | 14400 | 452 |

| 711KVE9152A | 3 | 711.2 | 914.4 | 387.35 | 317.5 | 3.3 | 6.4 | 6400 | 19300 | 585 |

| 711KVE9153E | 3-1 | 711.2 | 914.4 | 410 | 410 | 3.3 | 6.4 | 7000 | 20100 | 681 |

| 711KVE9155E | 3 | 711.2 | 914.4 | 425.45 | 387.35 | 8 | 6.4 | 6400 | 19300 | 675 |

| 785KVE1001E | 4-1 | 785 | 1 015 | 700 | 700 | 4 | 6 | 13500 | 41000 | 1460 |

| 825KVE1101E | 3 | 825.5 | 1 160 | 565 | 565 | 5 | 6 | 13900 | 33500 | 1890 |

Tel:+86-186 3793 0086

Fax:+86 379 6290 1536

Mail:sales@fv-bearing.com