Flat product rolling mills require well�engineered bearings that can operate at high speeds and withstand harsh environments, all while carrying heavy loads. At the same time, there’s constant pressure to increase productivity while reducing costs.

For more than 20 years, FV has provided high-quality bearings for rigorous applications in hot and cold rolling mills, while continuously improving the company’s bearings and seals to keep pace with the demands of the metals industry.

FV engineering experience and know-how are reflected in the newest sealed roll neck bearing design. It offers industry-leading tapered roller bearing design, combined with advanced proprietary sealing solutions to reduce contamination ingress and extend bearing life, expected to result in a lower cost-per-ton-rolled for mill operators.

IMPROVED MAIN SEAL DESIGN CAN SIGNIFICANTLY BOOST PERFORMANCE

Contaminants and water ingress can reduce bearing life and excessive grease loss can lead to increased maintenance costs or strip staining. FV technologists developed new, innovative seals that can address these operating concerns with a design that’s also easy for the maintenance professional to use, resulting in the integrated main seal design.

Leveraging 15 years of seal development expertise, FV costs or strip staining. technologists developed created innovative sealing solutions that may provide major benefits to mill operators, including:

• Longer bearing life due to improved sealing against water and contaminant ingress and maximum bearing load rating within the envelope.

• Potential for extended maintenance intervals due to reduced grease loss and contamination ingress.

• Lower cost of ownership due to less required maintenance and longer bearing life.

• Easy-to-assemble seals that reduce bearing maintenance time.

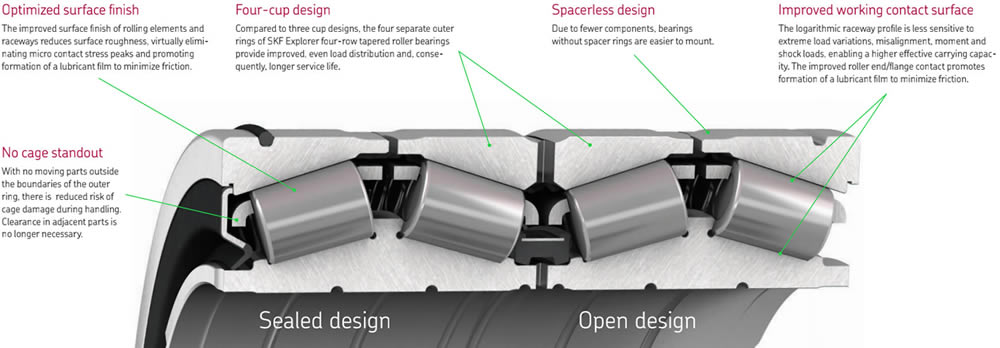

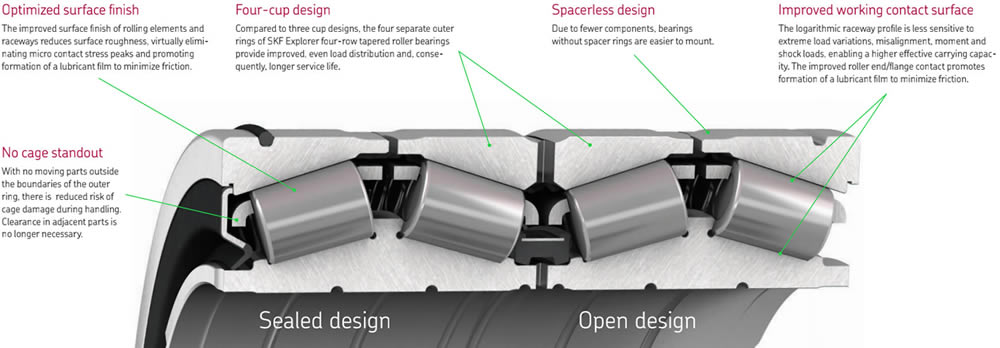

ENGINEERED FOR RELIABILITY UNDER HARSH CONDITIONS

Mill operators depend on high-performance bearings to keep their operations running smoothly. The FV roll neck bearing with an integrated seal can handle difficult working conditions, including high temperatures and speeds, as well as heavy shock loads and misalignment.

• Enhanced sealing due to high-performance seal designs with improved contact geometry.

• Improved performance in marginal lubrication due to better surface finishes.

• Misalignment accommodated by enhanced roller profiling for uniform load distribution.

• Increased toughness and fatigue life from case-carburized components.

• Improved load sharing provided by four single cups.

• Reduced cone face wear due to inboard and outboard cone face slots

• Reduced potential for roll neck damage due to spiral bore grooves with blended radii that provide lubricant access to the roll neck.

• Fewer components to handle due to advanced integrated design with no center spacers or seal carriers.

• More effective exclusion of contaminants from the chock bore due to sealing at cup outer diameter.

OPTIONAL FEATURES

PRE-GREASED ASSEMBLY: Bearings can be supplied as pre-greased assemblies. Several grease options are available, including FV Premium Mill grease, which is known for its excellent resistance to water washout. FV sealed roll neck bearings and seals are designed to work with different types of oil lubrication systems, as well. Contact your FV engineer for assistance with grease type, fill recommendations and applications in oil-lubricated systems.

SOLID CUP SPACERS: The standard sealed bearing can be re-lubricated in the chock through the holes in the cup spacers. For chocks which are not configured with lubrication lines, the sealed bearing can be provided with solid cup spacers.

CENTER DOUBLE CUP: The standard sealed bearing design contains four single cups; however, a double cup version is available upon request.