Whatsapp:+86-18638891360sales@fv-bearing.com

|

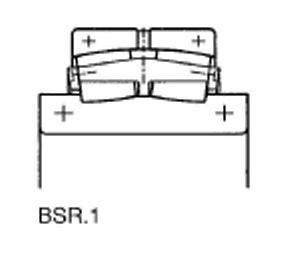

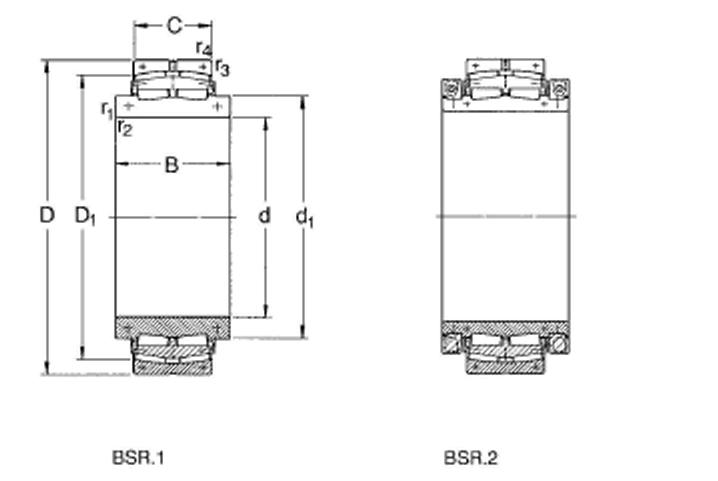

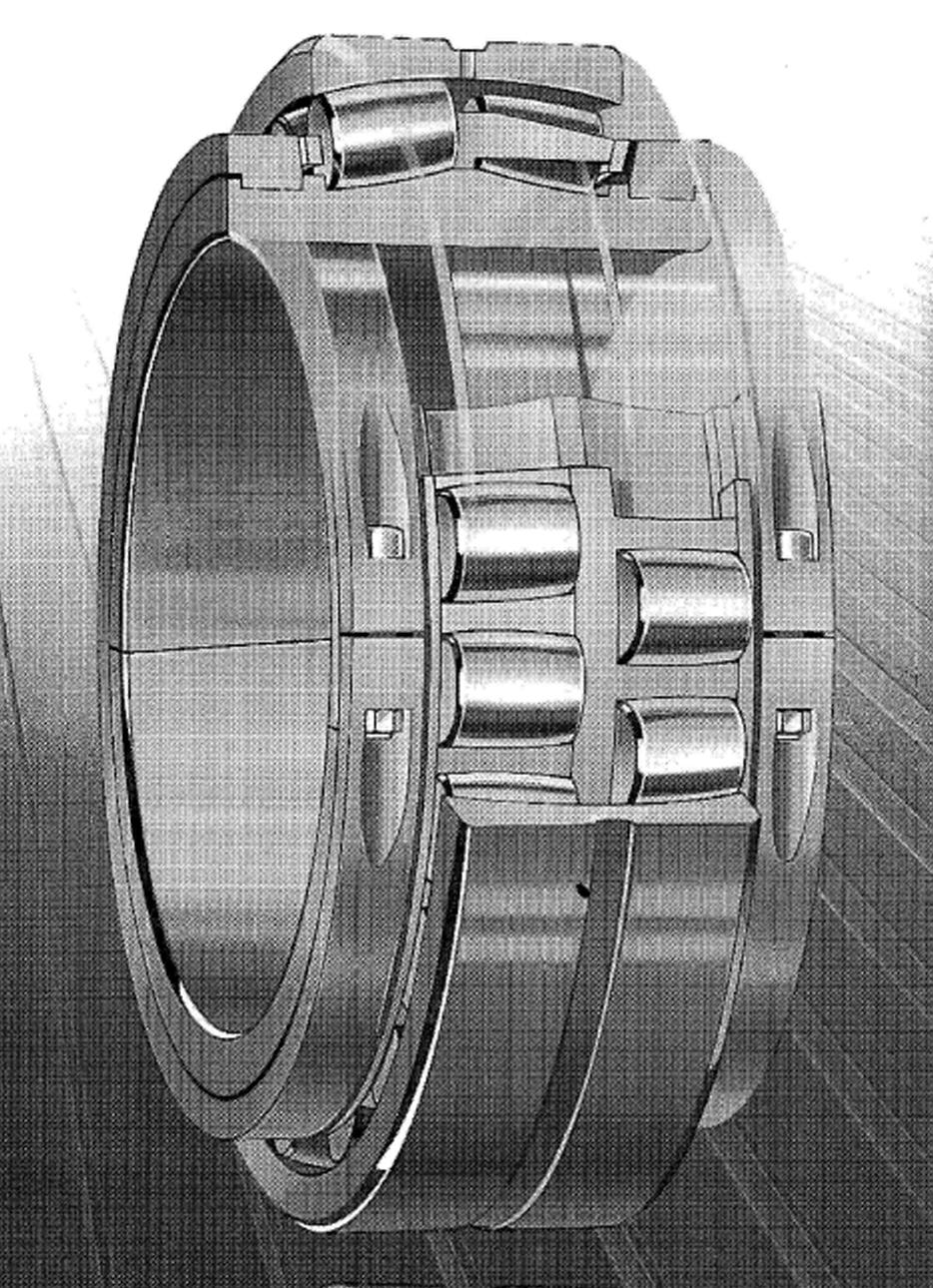

BSR.1 design

Inner ring screwed together. Two integral retaining flanges. Split inner ring centred machined brass cage.

|

|

|

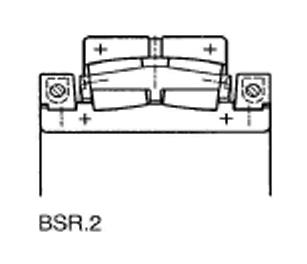

BSR.2 design

Inner ring with two integral retaining flanges. Loose split clamping rings. Split inner ring centred machined brass cage.

|

|

|

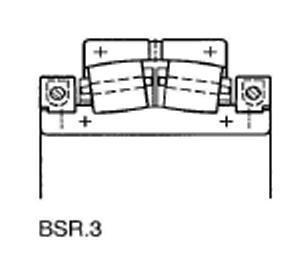

BSR.3 design

Inner ring with two integral retaining flanges. Loose split clamping rings. Split machined pin-type cage of steel.

|

|

|

|

|

| signation | Principal dimensions | Basic load ratings (kN) | Fatigue load limit | Mass | Design | Dimensions | Calculatlon factors | ||||||||||

| BEARING CODE | d | D | B | C | dynamic | static | kN | kg | - | d1 | D1 | r1.r2 | r3.r4 | e | Yi | Y2 | Y0 |

| C | Co | Pu | min | min | |||||||||||||

| BS2B321598 | 120 | 200 | 142 | 80 | 552 | 900 | 91.5 | 17 | BSR.1 | 166 | 169 | 11x45° | 2 | 0.37 | 1.8 | 2.7 | 1.8 |

| BS2B321606 | 140 | 230 | 102 | 53 | 368 | 600 | 60 | 14 | BSR.1 | 180 | 190 | 2 | 2 | 0.22 | 3 | 4.6 | 2.8 |

| BS2B321578 | 148 | 225 | 142 | 75 | 535 | 950 | 91.5 | 14 | BSR.1 | 180 | 197 | 2.1 | 2.1 | 0.3 | 2.3 | 3.4 | 2.2 |

| BS2B321610 | 180 | 300 | 125 | 74 | 713 | 1200 | 110 | 30 | BSR.1 | 220 | 248 | 2.1 | 2.1 | 0.24 | 2.8 | 4.2 | 2.8 |

| BS2B247534 | 280 | 500 | 260 | 176 | 2710 | 4660 | 345 | 175 | BSR.2 | 419 | 439 | 5 | 5 | 0.35 | 1.9 | 2.9 | 1.9 |

| BS2B247597 | 300 | 500 | 240 | 160 | 2710 | 4900 | 365 | 150 | BSR.2 | 418 | 434 | 5 | 5 | 0.3 | 2.3 | 3.4 | 2.2 |

| BS2B247307 | 360 | 540 | 220 | 134 | 2250 | 4500 | 325 | 155 | BSR.2 | 476 | 462 | 5 | 5 | 0.23 | 2.9 | 4.4 | 2 |

| BS2B243256 | 400 | 600 | 240 | 148 | 2880 | 5860 | 400 | 205 | BSR.2 | 522 | 541 | 5 | 5 | 0.23 | 2.9 | 4.4 | 2 |

| BS2B243485 | 420 | 620 | 233 | 150 | 2880 | 5860 | 400 | 215 | BSR.2 | 542 | 562 | 6 | 6 | 0.22 | 3 | 4.6 | 2.8 |

| BS2B243120 | 460 | 700 | 245 | 165 | 3280 | 6550 | 430 | 340 | BSR.2 | 604 | 635 | 6 | 6 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B242975D | 470 | 720 | 270 | 167 | 3570 | 7500 | 490 | 375 | BSR.2 | 646 | 656 | 6 | 6 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B247590 | 560 | 800 | 230 | 150 | 3340 | 8150 | 570 | 320 | BSR.1 | 669 | 742 | 5 | 5 | 0.17 | 4 | 5.9 | 4 |

| BS2B247087 | 560 | 870 | 330 | 200 | 5060 | 11000 | 710 | 580 | BSR.2 | 733 | 786 | 6 | 6 | 0.22 | 3 | 4.6 | 2.8 |

| BS2B243123 | 600 | 920 | 310 | 212 | 5640 | 12000 | 750 | 690 | BSR.2 | 798 | 837 | 9.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B243266 | 600 | 980 | 515 | 375 | 10400 | 21600 | 1320 | 1350 | BSR.2 | 811 | 833 | 7.5 | 7.5 | 0.35 | 1.9 | 2.9 | 1.8 |

| BS2B242989 | 630 | 920 | 310 | 212 | 5640 | 1000 | 570 | 630 | BSR.2 | 798 | 837 | 7.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B242994 | 670 | 980 | 350 | 230 | 6440 | 14000 | 850 | 800 | BSR.2 | 860 | 890 | 7.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B243122 | 710 | 950 | 375 | 243 | 5750 | 15300 | 900 | 700 | BSR.2 | 60 | 868 | 6 | 6 | 0.22 | 3 | 4.6 | 2.8 |

| BS2B247181 | 710 | 1030 | 360 | 236 | 7020 | 15600 | 930 | 860 | BSR.2 | 901 | 939 | 7.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B243125 | 750 | 1000 | 360 | 250 | 6330 | 17000 | 1040 | 710 | BSR.2 | 900 | 916 | 6 | 6 | 0.22 | 3 | 4.6 | 2.8 |

| BS2B243127 | 750 | 1090 | 475 | 335 | 9950 | 24000 | 1400 | 1300 | BSR.2 | 938 | 969 | 7.5 | 7.5 | 0.28 | 2.4 | 3.6 | 2.5 |

| BS2B243262 | 800 | 1060 | 370 | 250 | 6900 | 18600 | 1020 | 810 | 0SR.2 | 955 | 966 | 6 | 6 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B243124 | 850 | 1120 | 390 | 272 | 7360 | 20800 | 1220 | 830 | BSR.2 | 1005 | 1028 | 6 | 6 | 0.22 | 3 | 4.6 | 2.8 |

| BSR-8001 | 850 | 1180 | 331 | 206 | 6440 | 17000 | 1020 | 880 | BSR.2 | 1070 | 1100 | 6 | 6 | 0.15 | 4.5 | 6.7 | 4.5 |

| BSR-8000 | 850 | 1280 | 430 | 280 | 10100 | 23200 | 1340 | 1550 | BSn.2 | 1120 | 1177 | 7.5 | 7.5 | 0.2 | 3.4 | 5 | 3.2 |

| BS2B243268 | 850 | 1280 | 540 | 375 | 12400 | 31000 | 1900 | 2350 | BSR.2 | 1123 | 1147 | 7.5 | 7.5 | 0.26 | 2.6 | 3.9 | 2.5 |

| BS2B243126 | 900 | 1180 | 400 | 280 | 8170 | 22800 | 1340 | 1100 | BSR.2 | 1058 | 1086 | 6 | 6 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B243114 | 950 | 1250 | 420 | 300 | 8970 | 25500 | 1430 | 1300 | BSR.2 | 1130 | 1150 | 7.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2-0001 | 1020 | 1280 | 352 | 210 | 5900 | 19600 | 1100 | 950 | BSR.2 | 1192 | 1210 | 6 | 6 | 0.14 | 4.8 | 7.2 | 4.5 |

| 321489 | 1060 | 1460 | 500 | 335 | 11500 | 33500 | 1760 | 2470 | BSR.2 | 1330 | 1350 | 7.5 | 7.5 | 0.2 | 3.4 | 5 | 3.2 |

| BS2B243486A | 1060 | 1400 | 490 | 335 | 11300 | 32000 | 1760 | 1800 | BSR.2 | 1253 | 1204 | 7.5 | 7.5 | 0.21 | 3.2 | 4.8 | 3.2 |

| BS2B246572 | 1120 | 1460 | 500 | 335 | 11500 | 33500 | 1760 | 2070 | BSR.2 | 1330 | 1350 | 7.5 | 7.5 | 0.2 | 3.4 | 5 | 3.2 |

| BS2B243487CAB | 1120 | 1540 | 525 | 355 | 14400 | 44000 | 2400 | 2850 | BSR.3 | 1401 | 1420 | 7.5 | 7.5 | 0.2 | 3.4 | 5 | 3.2 |

| 321422A | 1250 | 1750 | 560 | 375 | 19600 | 50000 | 2600 | 3800 | BSR.2 | 1560 | 1607 | 9.5 | 9.5 | 0.19 | 3.6 | 5.3 |

3.6 |

Tel:+86-186 3793 0086

Fax:+86 379 6290 1536

Mail:sales@fv-bearing.com